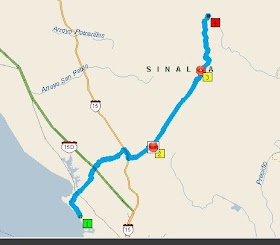

Saturday morning after a delightful breakfast at Torres we headed inland again, not quite as far this time, to the little town of La Noria - #4 on map. On the way back from La Noria we made a couple of other stops.

The road to La Noria was in very good shape this year. And much to our surprise there is a brand new arch leading into town. La Noria was founded in 1565 - another little town founded because of the mining in the area. Today it is know for its leather work.

Getting closer to town. Alternate means of transportation.

Looks like he has been grocery shopping

Still working on the road. A new bridge was/is going in here. Used to drive through a shallow dry wash. Now it is up a steep grade to the new cement bridge and down the other side.

Even the topes, speed bumps, have been redone. No more square one, it is not gently rounded. Heading towards the main part of town.

This is new too, a canon ball tope. It gets one's attention.

Stopping at our friend Roberto's leather shop. He makes tourist belts and trinkets and saddles to order.

Roberto in the brown shirt. This year he has more people working for him than in years past. Glad to see business is picking up again. One of his son's is now a radiologist and one more works for Roberto.

Some of saddles he has made for a special order. A local who is watching the gringos taking pictures.

A closer look at one. All hand made. Cutting and stitching and decorating. He buys the wooden frame which is also hand made. Saddles are cut and stitched in the shop. And he makes them to fit the rider.

His shop isn't very big and looks messy to us, but he does fine work. Some section of hides on the table. Dyes and chemical for the leather in the shelves.

This is a decorative aqueduct -sometimes it has water running from it. Looks like it also got a face-lift, new paint. It is right out the door from the leather shop. The blue building across the street is a museum, but I've never seen it open.

Across another street, this is the city hall where everyone goes to get marriage license and register births and deaths. Closed on

Saturday, otherwise it is usually quite busy.

Walking up the street. Bill and Roberto always have to have a long visit so we went walking. This is a storage warehouse for the flour used to make the tortillas.

Just a couple more buildings, homes and businesses. It appeared to me that several of the buildings were sporting new paint jobs since last time we were here.

Tortillas are made in this building. The kid who delivers them to the homes on his bike is loading up his cooler.

The meat market, which also sells cell phones. Out side beef is being cooked on the grill. Really smells good.

More home up by the school house.

Bill joined us and we crossed the street to another leather worker's shop. We went through the shop and out back. The back buildings were used by the Mexican Revolution army during the early 1900's. These were barracks and officer housing and stables

Every year they in more disrepair.

This rack holds what used to be form for making sandals. But they too are being eaten by termites or something.

The buildings are made of hand made adobe bricks covered with plaster.

The roof is getting ready to fall in.

This machine is from the mid 1800's it is used to thin down the pieces of leather. Years ago they ran a couple of pieced of hide through it for Bill to make them the thickness he needed. The only update on it is a very old electric motor. Notice the ceiling - original. The buildings were built in the late 1800's to very early 1900's

a look at the machine from a different view. What looks like sawdust is leather shavings.

The termites are doing a job on the roof. Most of the beams are almost rotted or eaten through.

Kind of inside the shop - the outside part of the working area. This machine used the metal forms on the floor to cut out the soles for the shoes. Years ago they made the sandals with tire rubber soles. Now the make then of a composite.

This worker is making a new seat for a vehicle. All leather cut, formed and stitched right here, probably by him.

This old machine cuts the leather into different sized strips.

A look at the business end of it. The strips are used to make the sandals.

A treadle sewing machine for decorative stitching.

The owner of this shop, Antonio. The shop has been run by his family for generations. He is polishing up a new pair of sandals.

Dying the leather brown for another pair of sandals. Snake skins hanging on the wall behind him.

Usable forms for different sizes of sandals. The sizes are written on them. From babies to big feet and everything in between.

An article that was in the paper about the town and the shop.

Of course we had to go up by the church. It too has been repainted. Last time we saw it it was tan with brown trim. The very first time we saw it it was pink and blue.

One of the faithful? Guess it is cooler inside than out.

From the church we went to yet another leather shop/factory. Here they specialize in sandals. Again there were more workers than we've seen before. A big piece of leather that strips for the shoes are cut from. Once we saw a young man cutting the strips by hand with a curved knife.

Weaving the leather strips into a sandal. He is doing it around a wooden foot form. Each boy can make 10 pairs of sandals a day. See the limes on the table? They are used to wet and cure the leather after the sandal is finished.

One shoe is finished. Behind it are the strips the young man uses.

This fellow is using something that looked like a brillo pad to smooth out the leather before it goes to the shoe maker.

The man in the back with the hat on was working on a part of a saddle.

Rubbing the lime on the finished shoe.

He is cutting soles for shoes.

Starting on a new pair of shoes. Making the slit to put the first piece of leather in. Nails it in place then pounds the nail flat.

Heading out of town up and over the new bridge.

The arch as we are leaving.

From La Noria we went to Los Ocunos Tequilla Distillry and then to the town of Puerto de Canoas for candy. Next blog.

Loved this blog. Thank you.

ReplyDeleteI appreciate your taking the time to let me know.

DeleteThank you.

It totally amasses me, the talent these people have. It seems they can make amazing things without a lot of modern equipment

ReplyDelete